In the realm of industrial operations, the efficiency of compressed air systems can significantly influence productivity and cost-effectiveness. Compressed air piping serves as the backbone of these systems, facilitating the delivery of compressed air to various tools and machinery. As industry expert Dr. Greg Simmons aptly stated, “The design and maintenance of compressed air piping can make or break an organization's operational efficiency.” This insight underscores the crucial role that proper piping systems play in maximizing the benefits of compressed air.

The selection of an appropriate compressed air piping system is not merely a technical decision but a strategic one that should align with an organization's operational goals. With numerous options available, choosing the right system can lead to enhanced performance, reduced energy consumption, and lower maintenance costs. In this article, we will explore the top 10 compressed air piping systems currently shaping the industry landscape, emphasizing their advantages and potential applications in various industrial settings. By examining these systems, we aim to provide valuable insights to engineers and facility managers looking to optimize their compressed air delivery processes.

Compressed air piping systems play a crucial role in industrial applications, serving as the backbone for various pneumatic tools and equipment. A recent industry report from the Compressed Air and Gas Institute (CAGI) highlights that approximately 70% of all industrial facilities rely on compressed air for their operations. A well-designed piping system ensures optimal air distribution, reducing pressure drops and energy consumption significantly. Efficient systems can enhance productivity, with studies showing that properly maintained compressed air systems can reduce energy costs by 20-30%.

When designing a compressed air piping system, it’s essential to consider factors such as material selection, pipe sizing, and layout. According to industry standards, the use of larger diameter pipes can help in minimizing pressure drops, particularly over long distances. Additionally, incorporating quick-connect fittings and strategically placed drains can mitigate moisture accumulation, which is a common issue in compressed air systems.

**Tips:** Regular maintenance is key to efficiency; inspect pipes for leaks often as even small leaks can lead to substantial energy losses. Furthermore, using a refrigerated air dryer helps ensure the air quality is suitable for sensitive applications, preventing damage to pneumatic tools and machinery. These simple practices can lead to significant savings and better overall system performance.

This chart showcases the efficiency ratings of various compressed air piping systems used in industrial applications. Ratings range from 1 to 10, reflecting the potential performance of each material in optimized compressed air flow and system reliability.

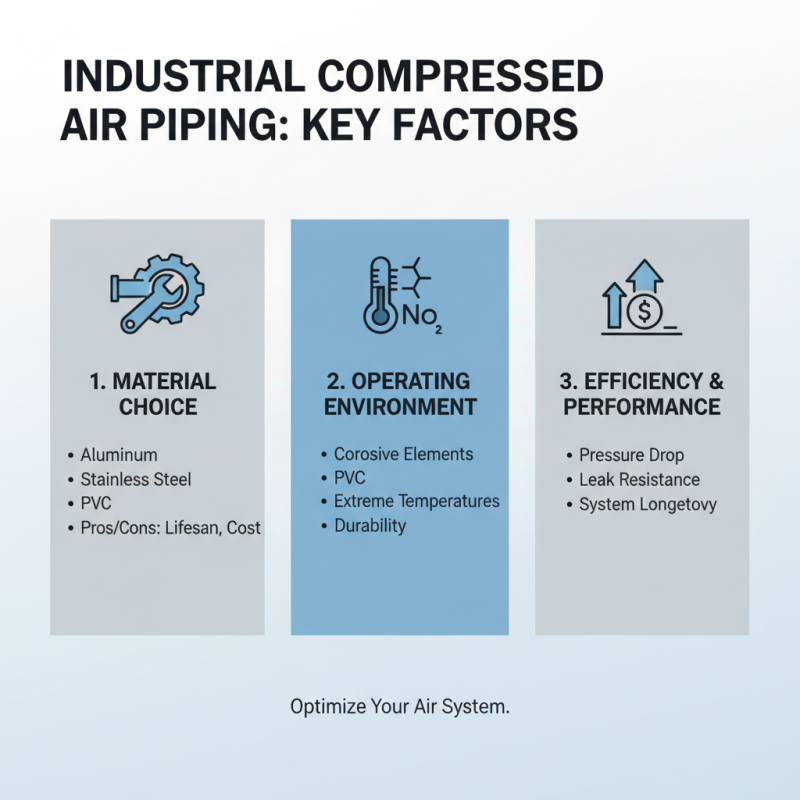

When selecting the right compressed air piping system for industrial use, it’s essential to consider several key factors that influence efficiency and performance. Firstly, the material of the piping plays a crucial role. Options like aluminum, stainless steel, or PVC come with their own set of advantages and disadvantages, impacting the lifespan and cost-effectiveness of the installation. Assessing the environment in which the system will operate, such as exposure to corrosive elements or extreme temperatures, will help determine the best material choice.

Additionally, the layout of the piping system should be optimized for airflow and minimal pressure loss. Long, convoluted runs can lead to inefficiencies, so it's best to design a system that minimizes bends and sudden changes in diameter. Ensuring that the piping system is properly sized according to the specific air demand of machinery and tools is also critical to avoid throttling and maintain system pressure.

**Tips**: Consider using software tools to model your piping design. This will help identify potential issues before installation and allow for adjustments that can enhance system efficiency. Regular maintenance checks can also extend the life of your piping system, catching leaks or corrosion before they become significant problems. Additionally, investing in high-quality fittings and connectors can drastically reduce air loss and improve overall performance.

Compressed air is a critical utility in many industrial operations, and the efficiency of piping systems significantly impacts overall performance. When selecting the right compressed air piping system, it’s essential to consider factors like material, pressure ratings, and installation methods. For instance,

aluminum piping systems are known for their lightweight design and resistance to corrosion, leading to lower operational costs and longer lifespan compared to traditional steel pipes. Moreover, the use of engineered pipe fittings can reduce pressure drops and enhance flow rates, contributing to energy savings of up to 30% according to industry reports.

Designing a compressed air piping system with optimal layout and minimal bends can further improve efficiency. Systems configured with fewer transitions and turns decrease turbulence, ensuring a stable air supply. A report by the Compressed Air and Gas Institute (CAGI) indicates that a well-planned piping system can reduce energy losses significantly, which can translate into considerable cost savings for facilities.

Tips: To maximize the efficiency of a compressed air piping system, regular maintenance checks are essential. Inspecting for leaks or blockages can prevent pressure losses. Additionally, training staff on proper usage can lead to better air management, potentially saving up to 20% in energy costs. Consider implementing a compressed air audit to identify areas for improvement and implement best practices in your operations.

When installing compressed air piping systems, adhering to best practices is crucial to ensure efficiency and minimize operational issues. One key aspect is the selection of materials and pipe sizes that are appropriate for the specific application. Opting for materials with high durability, such as aluminum or stainless steel, can significantly extend the lifespan of the system. Additionally, ensuring that the pipe diameter is suitable for the volume of air being transported helps reduce pressure drops and improves overall system efficiency.

Proper installation techniques are equally important. It is essential to maintain the correct slope in the piping to facilitate drainage of condensate, preventing water accumulation that can lead to corrosion and system failures. Furthermore, minimizing the number of fittings and joints can enhance the smooth flow of air and reduce the potential for leaks. Regular maintenance checks, including inspections for signs of wear and potential leak points, are also advisable to keep the system running optimally over time. By focusing on these installation best practices, industrial facilities can achieve a reliable and efficient compressed air piping system.

Maintaining an efficient air piping system is crucial for optimal performance in industrial settings. According to the Compressed Air and Gas Institute (CAGI), improper maintenance can lead to energy losses of up to 30% within compressed air systems. Regular inspections should focus on identifying leaks, which the U.S. Department of Energy estimates can waste approximately 20-30% of compressed air produced in a facility. Simple practices such as routinely checking connections and seal integrity can significantly reduce these losses.

In addition to leak detection, regular maintenance of air filters and dryers is essential to ensure the system operates within optimal parameters. The International Society for Automation (ISA) recommends changing filters as needed to maintain pressure stability, which can enhance overall system efficiency by 5-15%. Moreover, monitoring system pressure and air quality through technology can prevent larger failures and prolong the life of equipment. By prioritizing these maintenance practices, companies can not only boost productivity but also save on energy costs, reinforcing the importance of an effective strategy for managing air piping systems in any industrial application.

Please share your email with us to see your results.