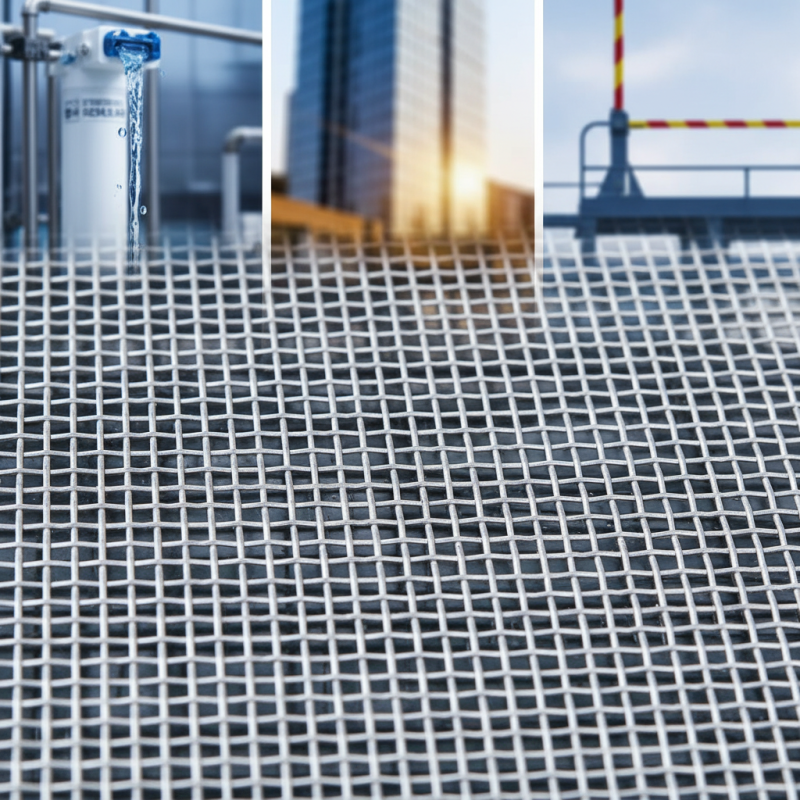

stainless steel woven wire mesh is a valuable material in various industries. It offers strength, versatility, and resistance to corrosion. According to John Smith, a leading expert in industrial materials, "Stainless steel woven wire mesh combines durability with excellent filtration properties." His insights highlight the material's significance.

This mesh serves multiple purposes. It is commonly used in filtration systems, architectural applications, and safety barriers. Many industries rely on its reliable performance. However, users should be aware of the need to choose the right specifications. Using improper mesh can lead to inefficiencies.

The intricate design of stainless steel woven wire mesh presents unique challenges. It may require careful installation and maintenance. As industries evolve, the demand for this material continues to grow. Understanding its properties and applications can help in making informed decisions. The journey to mastering stainless steel woven wire mesh is not straightforward, but it can be rewarding.

Stainless steel woven wire mesh is a unique material composed of interlaced stainless steel wires. This creates a sturdy and flexible structure. The weaving pattern can vary, affecting the mesh's properties. People often choose it for its corrosion resistance and durability. This mesh can withstand harsh environments, making it suitable for a variety of applications.

Commonly used in industrial settings, stainless steel woven wire mesh finds its place in filtration, guards, and separation processes. In food production, it ensures safety and hygiene. In construction, it provides support and stability. However, its cost can be a limiting factor for some. The installation process can also be tricky. Proper alignment is crucial for effectiveness, and this requires careful planning.

There are numerous styles and specifications available. This variety can lead to confusion. It's important to consider the specific needs of each project. Mistakes in choosing the right type can lead to failures in application. Each use case has its own requirements. Understanding these can help avoid common pitfalls associated with stainless steel woven wire mesh.

Stainless steel woven wire mesh is made from various grades of stainless steel. The material is known for its durability and resistance to corrosion. Commonly, it contains chromium and nickel. These elements enhance its strength and longevity. Depending on the specific application, the mesh can vary in thickness and hole size. This versatility makes it suitable for numerous uses.

In terms of properties, stainless steel wire mesh is not only strong but also flexible. It can withstand high temperatures without deformation. Additionally, its resistance to rust extends its lifespan, adapting well to outdoor conditions. The mesh can also be easily cleaned, which is essential in sanitary environments. However, not all grades perform the same in extreme conditions, requiring careful selection for specific applications.

While it offers many advantages, there are challenges too. Some types of woven wire mesh may not be as conductive as other materials. This can limit usage in certain electrical applications. Additionally, the cost might be a concern for budget-sensitive projects. Hence, it's important to weigh the benefits against these factors before making a decision.

Woven wire mesh is made from stainless steel wires. It has various applications across different industries. The manufacturing process plays a key role in its quality and functionality. Several methods can produce woven wire mesh, each with unique characteristics.

One common method is plain weaving. In this technique, wires are woven in a simple over-and-under pattern. The result is a strong mesh that is often used for filtration. Twill weaving is another approach, creating a distinct diagonal pattern. This method offers enhanced flexibility and is suitable for applications where high strength is required.

Both processes have their challenges. Plain weaving can be limited in terms of strength and flexibility. Twill weaving, while more versatile, might be more complex to produce. Manufacturers must consider these factors when choosing a method. The right process depends on the specific needs of the project. Quality control during production is essential to ensure durability and performance.

Stainless steel woven wire mesh is highly versatile. Its application spans multiple industries. In the food industry, it is used to filter and separate materials. The mesh allows for efficient processing while ensuring hygiene. For example, it can help in sieving flour or separating fine particles from liquids.

In the construction sector, this mesh provides excellent support and reinforcement. It can be found in concrete forms or as a barrier in various structures. Its corrosion resistance makes it a preferred choice outdoors. However, sometimes the mesh can rust if not properly maintained. The challenge is ensuring that it remains protected from environmental factors.

Another significant application is in the petrochemical industry. Here, stainless steel woven wire mesh serves as straining material to prevent unwanted contaminants. While it works effectively, the need for regular inspections is critical. Mesh can wear down over time, affecting its performance. Thus, understanding its limitations is essential for safety and efficiency in various operations.

| Industry | Application | Mesh Type | Wire Diameter (mm) | Additional Features |

|---|---|---|---|---|

| Food Processing | Filtration | Plain weave | 0.5 | Corrosion resistant |

| Construction | Reinforcement | Dutch weave | 1.0 | High tensile strength |

| Mining | Separation | Square weave | 1.5 | Durability against abrasion |

| Pharmaceutical | Containment | Twill weave | 0.3 | Chemical resistance |

| Aerospace | Filter systems | Leno weave | 0.4 | Lightweight |

Stainless steel woven wire mesh is widely appreciated for its versatility and durability. This type of mesh is made by weaving stainless steel strands together, creating a strong yet flexible material. Its resistance to rust and corrosion makes it ideal for various projects.

The benefits of using stainless steel woven wire mesh are numerous. It enhances design aesthetics while maintaining functionality. It can be used in architectural features, such as railings and partitions, adding a modern touch. Additionally, it serves practical purposes in filtration and security applications. The mesh is lightweight, yet it can provide robust support in many designs.

Tips: When choosing woven wire mesh, consider the space and the purpose. Not all meshes fit every project. The mesh's openness and weave pattern can affect airflow and visibility. Understand these factors to make the best choice.

Moreover, working with stainless steel woven wire mesh may require adjustments for specific contexts. Cuttings and fittings might not always align perfectly. Take time to measure and plan your design carefully. Flexibility in adaptations can lead to better outcomes. This material can sometimes be tricky to install, but the final result is rewarding.

Please share your email with us to see your results.