In today's industrial landscape, the demand for efficient and reliable air compression solutions is ever-increasing. One of the most effective options available is the screw type air compressor, known for its durability and performance. Unlike traditional piston compressors, screw type air compressors utilize a rotary mechanism that provides a continuous supply of compressed air, making them ideal for various industrial applications. Their ability to handle high volumes of air with minimal noise makes them particularly favorable for manufacturing environments where operational efficiency is crucial.

Moreover, screw type air compressors are engineered for longevity and reduced maintenance costs, as their fewer moving parts lead to less wear and tear over time. This not only translates into significant cost savings but also ensures that businesses can maintain consistent production levels without the fear of unexpected downtime. Additionally, the energy efficiency of these compressors stands out, as they can operate effectively even at fluctuating demand levels, further enhancing their appeal for industrial users looking to optimize resource usage.

Choosing a screw type air compressor ultimately means investing in a reliable, efficient, and low-maintenance solution that meets the varying needs of industrial applications. As industries continue to evolve, relying on such advanced technology prompts businesses to stay competitive while enhancing productivity and performance.

When selecting an air compressor for industrial applications, several critical factors must be considered to ensure optimal performance and efficiency. One of the primary considerations is the required airflow and pressure levels specific to the tasks at hand. Understanding the demands of your operations will guide you in choosing a compressor that not only meets these requirements but also operates efficiently within your facility's constraints. An adequate assessment of airflow needs, typically measured in cubic feet per minute (CFM), is essential, as insufficient airflow can lead to downtime and compromised operational efficiency.

Additionally, energy efficiency is a significant factor in the selection process. A screw-type air compressor is often favored because it tends to provide higher efficiency levels compared to other compressor types. This is especially important for industries that rely on compressed air for continuous operations, as energy costs can quickly add up. Moreover, durability and maintenance needs should be evaluated; screw compressors usually feature lower maintenance requirements due to their design, particularly if they're built for heavy-duty use. Assessing the environment where the compressor will be used—factors such as temperature, humidity, and available space—will also aid in making a well-informed decision that aligns with your industrial needs.

Screw type air compressors have gained popularity in industrial applications due to their numerous advantages over other types of compressors, such as reciprocating or rotary vane compressors. One of the primary benefits of screw type compressors is their efficiency. They can operate continuously, providing a steady flow of compressed air without the interruptions commonly associated with piston compressors. This continuous operation leads to lower energy costs and increased productivity in industrial settings, making them a cost-effective choice over time.

Another significant advantage of screw type compressors is their durability and low maintenance requirements. The design of these compressors minimizes wear and tear, resulting in a longer lifespan compared to other compressor types. Additionally, most screw compressors feature oil-injected designs, which help to maintain optimal operating temperatures and reduce the risk of overheating. This reliability is crucial for industries that depend heavily on compressed air for their operations, as it ensures minimal downtime and consistent performance.

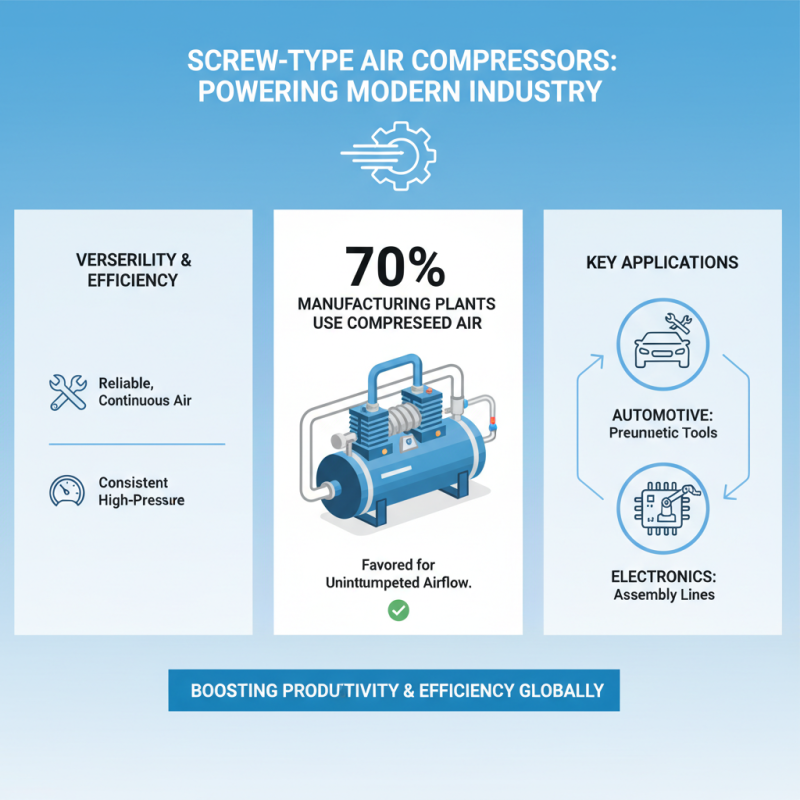

Screw type air compressors are increasingly recognized for their versatility and efficiency across various industries. One of the most notable applications is in the manufacturing sector, where reliable and continuous air supply is vital. Reports indicate that more than 70% of manufacturing plants utilize compressed air systems, with screw compressors being favored for their ability to provide a consistent airflow and maintain high-pressure levels. In industries such as automotive and electronics, screw compressors power critical operations such as pneumatic tools and assembly lines, ensuring productivity and efficiency.

Additionally, the construction industry greatly benefits from the use of screw type air compressors. According to a recent industry report, around 60% of construction sites employ mobile screw compressors to facilitate tasks such as drilling, demolition, and concrete spraying. These compressors are not only portable but also designed to withstand harsh environmental conditions, making them ideal for outdoor applications. Furthermore, their energy efficiency can lead to significant cost savings, with some studies suggesting that businesses can reduce energy consumption by up to 30% when switching from traditional compressors to high-performance screw type units. Such efficiency is pivotal in an industry where operational costs can significantly impact profitability.

Maintaining a screw type air compressor is essential for optimizing performance and prolonging its lifespan. According to the Compressed Air and Gas Institute (CAGI), proper maintenance can improve energy efficiency by up to 30%, significantly reducing operational costs. Regular tasks such as checking oil levels, replacing filters, and inspecting air intake conditions not only enhance reliability but also ensure the compressor operates at peak efficiency. A study by the U.S. Department of Energy highlights that unplanned downtime can cost industries up to 20% in lost production, emphasizing the financial benefits of a proactive maintenance schedule.

Another critical aspect of screw compressor maintenance is monitoring operating temperatures. Excessive heat can lead to premature wear and tear, reducing the compressor's lifespan. The American Society of Mechanical Engineers (ASME) recommends keeping the discharge temperature within specified limits to prevent thermal degradation of key components. Implementing a systematic lubrication schedule is also vital; using high-quality, manufacturer-recommended lubricants can further reduce friction and wear, enhancing overall system performance. Regularly reviewing maintenance logs and setting up alerts for filter changes and service intervals ensures that maintenance practices are not only followed but also continuously improved, leading to an efficient air compression system that meets industrial demands effectively.

| Dimension | Description | Best Practices |

|---|---|---|

| Oil Injection | Used for lubrication and cooling of the compressor | Regularly check oil levels and change oil as per manufacturer's recommendations. |

| Air Quality | Maintains consistent pressure and flow of clean air | Install filters and replace them regularly to ensure air purity. |

| Heat Management | Prevents overheating of components | Ensure airflow is unobstructed and clean heat exchangers. |

| Vibration Analysis | Monitors mechanical condition | Conduct vibration checks monthly to identify issues early. |

| Belt Tension | Ensures proper engagement of components | Check and adjust belt tension quarterly to avoid slippage. |

| Inspection Schedule | Regular checks of compressor condition | Establish a biannual inspection routine conducted by trained professionals. |

When considering the operational efficiency of an industrial facility, cost savings and energy optimization are paramount. Screw type air compressors exhibit a design that inherently promotes energy savings through their continuous flow and high efficiency. The mechanism allows for a consistent supply of compressed air, reducing the start-stop cycles that characterize traditional compressors. This sustained operation translates directly to lower energy consumption, making them an ideal choice for industries aiming to minimize their utility costs while maximizing productivity.

Furthermore, the maintenance costs associated with screw type compressors are typically lower when compared to other types of compressors. Their construction is robust, leading to fewer breakdowns and less frequent servicing requirements. The longevity of these machines means that the initial investment can be offset by the extended lifetime and significant operating savings over time. In sectors where compressed air is vital to applications, opting for screw type technology not only meets the demands for efficient performance but also contributes to overall economic sustainability within the industrial landscape.

Please share your email with us to see your results.