As we advance towards 2025, the industrial compressor sector is poised for significant transformation, driven by the need for enhanced efficiency and sustainability. Industry expert Dr. Amelia Knight, a renowned authority on compressor technology, states, "The future of industrial compressors lies in their ability to adapt and innovate, ensuring peak performance while minimizing energy consumption." This sentiment reflects the critical shift in focus within the industry towards smarter, more efficient systems capable of meeting the growing demands of various applications.

In the coming years, we anticipate several key trends that will reshape the landscape of industrial compressors. From the integration of advanced automation technologies to the development of environmentally-friendly refrigerants, these advancements not only aim to streamline operational processes but also address the pressing need for sustainability. By examining these trends, businesses can harness the potential of industrial compressors to drive operational excellence and cost-effectiveness.

As organizations strive to optimize their production capabilities, understanding these evolving trends will be essential. Embracing change and staying ahead of the curve in the industrial compressor market will ultimately be pivotal in achieving maximum efficiency and ensuring a competitive edge in a rapidly evolving industrial environment.

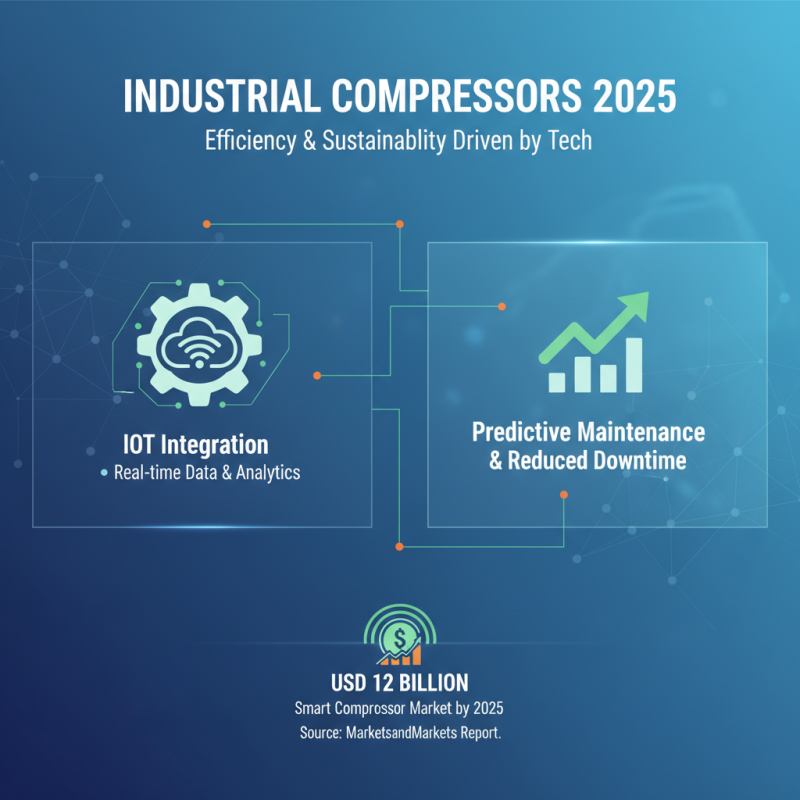

As we look ahead to 2025, the industrial compressor sector is poised for significant advancements driven by emerging technologies that promise to enhance operational efficiency and sustainability. One of the most notable trends is the integration of IoT (Internet of Things) capabilities within compressor systems. By leveraging real-time data and analytics, companies can monitor compressor performance more effectively, leading to predictive maintenance and reduced downtime. According to a report by MarketsandMarkets, the global smart compressor market is projected to reach USD 12 billion by 2025, underscoring the growing demand for intelligent systems in industrial applications.

Additionally, advancements in energy efficiency are at the forefront of industrial compressor innovations. The implementation of variable speed drives (VSDs) has gained traction, allowing compressors to adjust their speed based on demand rather than operate at a constant rate. This technology not only optimizes energy consumption but can reduce energy costs by up to 30%. Furthermore, the increasing regulation of greenhouse gas emissions is pushing manufacturers toward more environmentally friendly refrigerants and designs that minimize carbon footprints. A report from Research and Markets highlights that the move towards eco-efficient compressors will form a critical part of strategic initiatives in many industries, indicating a shift towards sustainability that is increasingly influencing technology development in the sector.

As industries aim for greater efficiency and reduced environmental impact, sustainability practices are becoming integral to compressor operations. In 2025, we can expect a significant shift towards eco-friendly technologies that enhance compressor performance while minimizing energy consumption.

One of the most impactful practices will be the integration of advanced materials and designs that enhance the thermal efficiency of compressors. Utilizing lightweight, durable materials not only reduces energy expenditure but also extends the lifespan of the equipment.

Furthermore, the adoption of smart technologies will play a crucial role in optimizing compressor efficiency. IoT devices and machine learning algorithms will enable real-time monitoring of operational performance, leading to predictive maintenance and operational adjustments that can dramatically reduce energy wastage. These innovations not only drive down operational costs but also align with sustainability goals by lowering the carbon footprint associated with industrial processes.

As the industry trends towards comprehensive sustainability practices, we are likely to see a convergence of efficiency and environmental responsibility in compressor technology, paving the way for a more sustainable future in industrial operations.

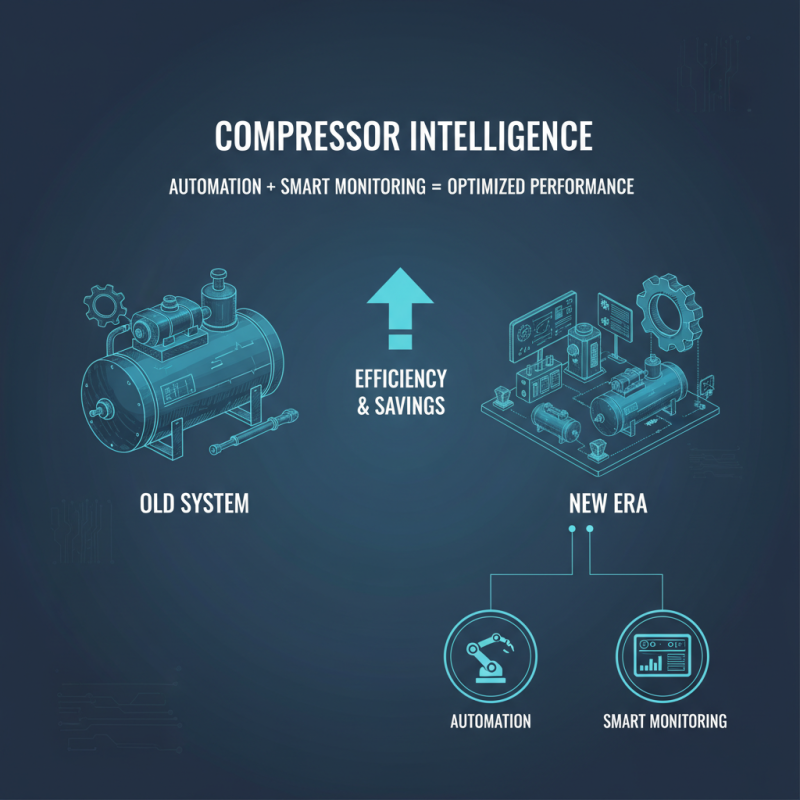

The industrial landscape is rapidly evolving, and the integration of automation and smart monitoring in compressor systems is becoming paramount for achieving maximum efficiency. As companies strive to enhance productivity and reduce operational costs, the role of advanced technologies in compressor management is more critical than ever. Automation allows for precise control of compressor functions, reducing human error and optimizing performance in real-time. Meanwhile, smart monitoring systems equip operators with data analytics and performance insights, enabling informed decision-making and proactive maintenance.

**Tips:** Implementing an automated monitoring system can drastically improve your compressor performance. By enabling remote access to data and alerts, you can quickly respond to any issues before they escalate, ensuring continuous operation and minimal downtime. Integrating predictive maintenance tools within your compressor systems can help anticipate failures and address them before they result in costly repairs.

Moreover, as the demand for energy efficiency grows, automated systems offer the ability to adapt compressor operations based on current workload and atmospheric conditions. This adaptability not only conserves energy but extends the lifespan of the equipment. As industrial practices move toward sustainability, leveraging these smart technologies will position companies as leaders in efficiency and innovation.

**Tips:** Regularly review the analytics provided by your smart monitoring system to identify trends in energy usage and performance. This practice not only helps in assessing efficiency but also in pinpointing opportunities for further optimization. By continually refining operations based on real-time data, businesses can achieve significant cost savings and enhance overall effectiveness.

The implementation of Industry 4.0 is redefining compressor operations, driving efficiency and effectiveness across the industrial landscape. With the integration of IoT (Internet of Things) technology, compressors are now equipped with smart sensors that monitor real-time performance data. According to a report by McKinsey, industries that adopt IoT solutions can achieve a productivity increase of up to 30%. This connectivity allows for predictive maintenance, reducing unplanned downtimes by signaling potential failures before they occur, thus significantly enhancing operational reliability.

Moreover, as manufacturers increasingly rely on data analytics, compressor operations can be optimized through real-time adjustments based on operational conditions. A study by the International Energy Agency highlights that businesses leveraging advanced data analytics to optimize energy consumption can cut energy usage by as much as 10-15%. This not only promotes sustainability but also leads to substantial cost savings in energy expenses. Therefore, embracing the principles of Industry 4.0 not only transforms compressor operations but also contributes to a broader movement towards efficient and sustainable industrial practices.

This chart illustrates the projected trends in industrial compressor efficiency improvements driven by Industry 4.0 advancements. The data shows the expected percentage improvements in efficiency from various technological innovations in 2025.

In 2025, businesses will increasingly seek cost-effective solutions for optimizing industrial compressor systems to enhance efficiency and reduce operational expenses. One key trend is the integration of advanced monitoring technologies that provide real-time data on compressor performance. These monitoring systems utilize IoT capabilities to track energy consumption, detect inefficiencies, and predict maintenance needs, enabling companies to make informed decisions that can extend the lifespan of their compressors while minimizing downtime.

Another significant trend involves the adoption of alternative energy sources and environmentally friendly refrigerants in compressor systems. As industries strive to meet sustainability goals, transitioning to renewable energy-powered compressors reduces reliance on fossil fuels and lowers carbon footprints. Additionally, using eco-friendly refrigerants not only complies with regulatory standards but also helps enhance the energy efficiency of the entire system. By embracing these innovative practices, businesses can achieve significant cost savings while contributing to a greener future.

| Trend | Description | Expected Impact | Cost-Effectiveness |

|---|---|---|---|

| Smart Compressors | Integration of IoT and AI for predictive maintenance and real-time monitoring | Enhanced reliability and reduced downtime | Higher initial investment but significant long-term savings |

| Energy-Efficient Technology | Use of advanced materials and designs to reduce energy consumption | Lower operational costs and reduced carbon footprint | Cost savings on energy bills and tax incentives |

| Modular Design | Flexible systems that allow for easy upgrades and scaling | Adaptable to changing operational needs | Initial investment spread over time through phased implementation |

| Refrigerant Innovations | New refrigerants with lower Global Warming Potential (GWP) | Compliance with environmental regulations and improved efficiency | Reduction in potential penalties and costs associated with non-compliance |

| Enhanced Automation | Integration of automation for streamlined operations and less manual oversight | Improved efficiency and lower labor costs | Initial costs offset by labor savings and increased productivity |

Please share your email with us to see your results.