Choosing the right compressors for your business is a crucial decision that can significantly impact your operational efficiency and productivity. With numerous options available on the market, it can be overwhelming to determine which type of compressor best suits your specific needs. This guide aims to provide you with essential tips that will aid in selecting the most appropriate compressors for your applications, ensuring that you balance performance, cost, and energy efficiency. From understanding the different types of compressors to evaluating your business requirements, these insights will empower you to make informed choices. Whether you are in manufacturing, construction, or another industry that relies on compressed air, this article will serve as a valuable resource to streamline your decision-making process and enhance your overall business performance.

When selecting the right compressor for various industries, several critical factors must be considered to ensure efficiency and compatibility with specific applications. Notably, the global industrial air compressor market is projected to grow dynamically, with estimates indicating an increase from USD 26.81 billion in 2024 to approximately USD 40.18 billion by 2033. This growth underscores the importance of understanding industry-specific needs, such as required pressure levels, airflow rates, and the type of compressed air needed, whether for pneumatic tools, packaging, or food processing.

Moreover, the oil-free screw compressor segment has become increasingly vital, especially in sectors like food and beverage, where contamination risks demand stringent standards. Market analysis reveals that as sustainability and health regulations tighten, the demand for oil-free solutions is rising, leading to a significant share in market growth. Additionally, in the gas compressor sector, the market size is expected to reach $9.5 billion by 2034, highlighting an ongoing trend towards more efficient, environmentally friendly compressor technologies. Such data emphasizes the necessity of careful consideration before selecting compressors that align with operational requirements and regulatory standards across multiple industries.

When choosing the right compressor for your business, understanding the various types and their specific applications is essential. In recent years, the market for variable refrigerant flow (VRF) systems has seen significant growth, rising from $177 billion in 2021 to an expected $284.6 billion by 2028, indicating a compound annual growth rate (CAGR) of 7.02%. This growth reflects the increasing demand for energy-efficient systems that adapt to varying load conditions, highlighting the importance of selecting compressors that align with your operational needs.

Additionally, the automotive air conditioning compressor market is projected to grow from $1.013 billion in 2024 to $1.217 billion by 2032, with a modest CAGR of 2.31%. As consumers seek energy-efficient and high-performance options, businesses must consider compressors that provide reliability and advanced technology. Likewise, the HVAC industry's transition to variable frequency drives signifies an essential trend; these systems allow for greater control and efficiency, better aligning with today's smart technology demands. Understanding these trends allows businesses to select compressors that maximize both performance and efficiency tailored to their specific applications.

When selecting the right compressors for your business, evaluating energy efficiency is a critical consideration, especially in light of recent advancements in energy optimization across various industries. A study on CO2 capture and compression in natural gas combined cycle power plants highlights the importance of reducing energy consumption through configuration modifications. By integrating processes and recovering waste heat, significant energy savings can be achieved, which is essential for minimizing operational costs and environmental impact.

Moreover, the performance analysis of rotary compressors demonstrates that operating at optimal speeds can enhance efficiency. Insights from research on heat pumps also reveal that data-driven assessments can lead to improved energy management in residential applications. As businesses consider their compressor options, leveraging findings from these studies can guide decisions that prioritize energy efficiency, ultimately supporting sustainability goals and reducing the carbon footprint. Implementing advanced technologies and methodologies, such as the assessment of shaped nozzles within pipeline systems, can further optimize energy use and improve the reliability of compressed gas systems.

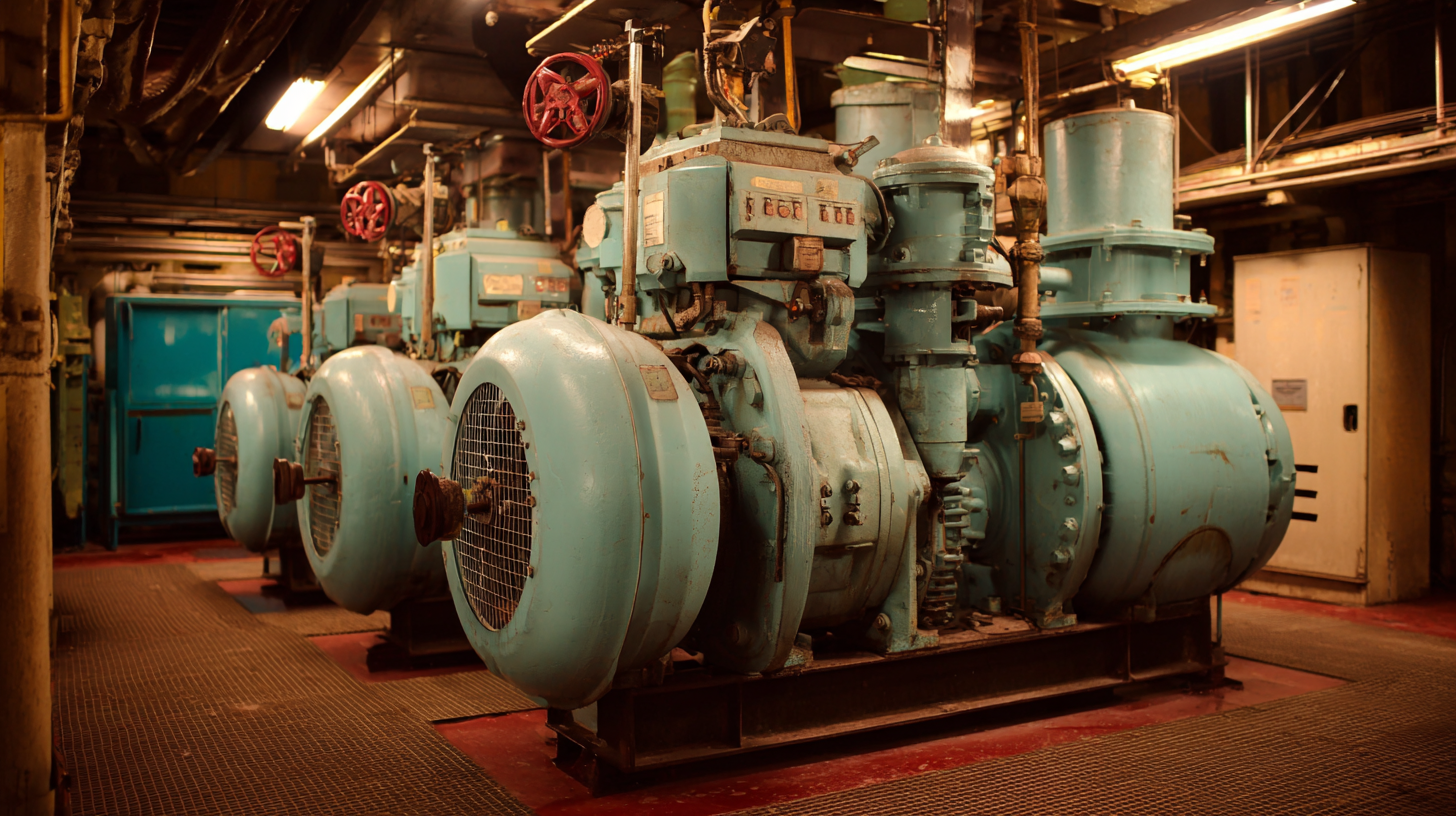

When selecting compressors for your business, assessing maintenance and durability is crucial. A durable compressor can withstand the rigors of daily operations, reducing the frequency of repairs and potential downtimes. Look for models constructed with high-quality materials and backed by reputable brands known for their longevity and reliability in the industry.

Another essential tip is to consider the ease of maintenance. Choose compressors that are designed for accessibility, allowing your team to perform routine checks and repairs with minimal hassle. Regular maintenance not only extends the lifespan of the equipment but also ensures optimal performance. Opt for compressors that offer user-friendly features, such as removable panels and centralized lubrication systems, which simplify the upkeep process.

Additionally, it's important to evaluate the warranty and service options available. A good warranty can provide peace of mind, while responsive service can be invaluable in case of unexpected issues. By focusing on maintenance and durability, you can make a more informed decision that will benefit your business in the long run.

When selecting a compressor for your business, understanding the balance between initial investment and long-term savings is crucial. According to a report by the U.S. Department of Energy, air compressors can account for up to 30% of a manufacturing facility's energy consumption.

Therefore, choosing an energy-efficient model can significantly reduce operational costs over time. For instance, a higher initial investment in a variable-speed compressor may lead to savings of over 25% on energy bills when compared to traditional fixed-speed models, as these compressors adjust their output based on demand.

Moreover, maintenance costs should also be factored into your cost analysis. A study from the Compressed Air & Gas Institute indicates that regular maintenance can save businesses up to 40% on repairs and extend the lifespan of compressors by five years or more. By investing in a reliable compressor with lower maintenance requirements, businesses can better allocate resources towards growth rather than unforeseen equipment failures. Ultimately, a thorough cost analysis weighing both initial and long-term expenses will lead to more informed and beneficial compressor choices.

Please share your email with us to see your results.