In today's manufacturing and industrial sectors, the efficient installation of compressed air piping is crucial for optimizing performance and reducing operational costs. According to a report by the Compressed Air and Gas Institute (CAGI), nearly 30% of a facility's energy consumption can be attributed to compressed air systems, making it essential to design and install these systems with care. Properly executed compressed air piping not only enhances system efficiency but also minimizes leaks and pressure drop, which can lead to significant energy waste. The United States Department of Energy also highlights that poorly designed piping can result in energy losses ranging from 20% to 30%. Therefore, understanding how to efficiently install compressed air piping is vital for industries looking to enhance productivity while simultaneously lowering energy costs and ensuring sustainable practices.

When selecting the right material for compressed air piping, several key considerations come into play that directly impact both efficiency and overall performance. One major factor is the pressure rating of the material, as improper ratings can lead to system failures or inefficiencies. According to a report by the Compressed Air and Gas Institute (CAGI), steel pipes can typically handle higher pressures than plastic alternatives, making them a preferable choice in high-demand applications where durability and safety are paramount.

Another important consideration is the air quality and temperature of the environment in which the piping will operate. For example, aluminum piping is known for its resistance to rust and corrosion, making it suitable for humid and moist conditions. A study from the Department of Energy indicates that using appropriately rated materials can enhance the efficiency of air flow by as much as 15%, thereby reducing energy consumption and operational costs over time. Ultimately, choosing the correct piping material not only ensures system reliability but also contributes significantly to operational efficiency and cost savings.

When installing compressed air piping, having the right tools and equipment is essential for achieving maximum performance and efficiency. First and foremost, a comprehensive tool kit should include pipe cutters, deburring tools, and wrenches specifically designed for the piping materials being used. Pipe cutters ensure clean, precise cuts, which reduce the risk of leaks. Deburring tools help smooth out sharp edges, preventing potential hazards and ensuring proper fittings when connecting pipes. Additionally, adjustable wrenches or socket sets are crucial for tightening fittings to the required specifications without damaging the pipes.

When installing compressed air piping, having the right tools and equipment is essential for achieving maximum performance and efficiency. First and foremost, a comprehensive tool kit should include pipe cutters, deburring tools, and wrenches specifically designed for the piping materials being used. Pipe cutters ensure clean, precise cuts, which reduce the risk of leaks. Deburring tools help smooth out sharp edges, preventing potential hazards and ensuring proper fittings when connecting pipes. Additionally, adjustable wrenches or socket sets are crucial for tightening fittings to the required specifications without damaging the pipes.

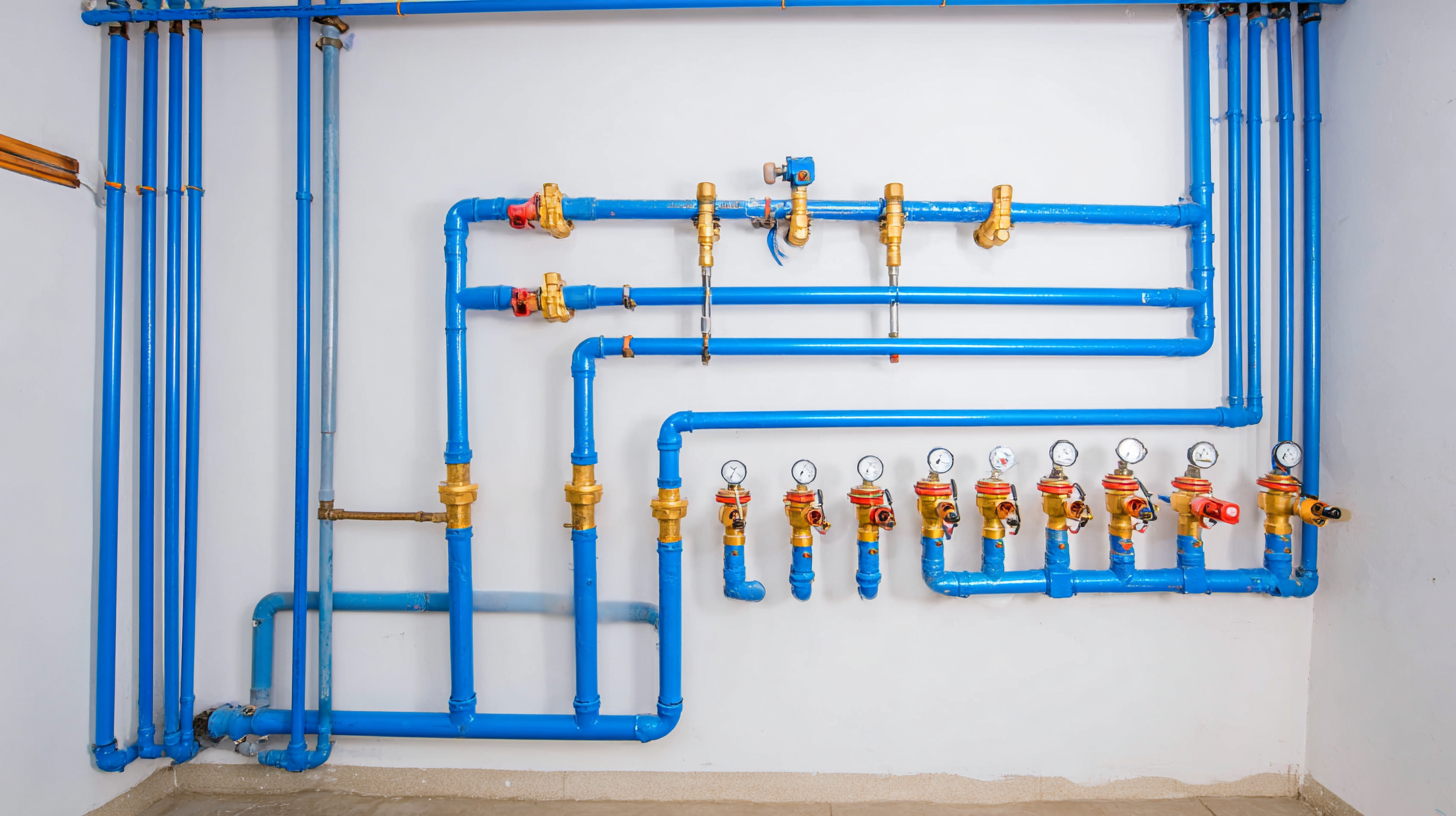

Beyond basic hand tools, investing in specialized equipment can significantly enhance the installation process. A pipe threading machine is beneficial for those using metal piping, allowing for quick and accurate threading, while an air compressor with a pressure gauge is vital for testing the system once installed. Moreover, installing a piping manifold can help organize connections and improve overall air distribution throughout your facility. With the appropriate tools and equipment in hand, you're set to ensure an efficient and effective compressed air piping installation that meets the demands of your operations.

Designing an efficient compressed air system begins with a thorough understanding of your specific needs and operational requirements. Start by assessing the air quantity and quality needed for your applications. This involves analyzing the tools and equipment that will be connected to the system, as well as any future expansions you might anticipate. A detailed layout should be created, considering both the layout of the workspace and the optimal distances between various components. This planning stage is crucial to avoiding bottlenecks that can significantly affect the overall performance of the system.

Once you have a layout in place, focus on selecting the right materials for the piping. High-quality, corrosion-resistant materials are essential to ensure longevity and performance. Additionally, the diameter of the pipes should be chosen based on the air flow requirements – larger diameters reduce pressure drop and energy loss. When installing the piping, utilize proper fittings and minimize sharp turns to ensure a smooth flow. Finally, regular maintenance and monitoring of the system are vital to addressing issues early and maintaining peak efficiency. By following these steps, you can create a design that maximizes performance and reliability in your compressed air system.

When installing compressed air piping, avoiding common mistakes is crucial to ensure maximum efficiency and performance. One of the most prevalent errors is neglecting proper sizing of the pipes.

According to the Compressed Air and Gas Institute (CAGI), incorrect pipe sizing can lead to pressure drops of up to 30%, significantly diminishing system performance. It is imperative to calculate the optimal pipe diameter based on the total length of the run and the required flow rate to maintain adequate pressure levels throughout the system.

Another frequent mistake is overlooking the importance of proper layout and installation techniques. Poorly designed systems may have unnecessary bends, excessive lengths, or insufficient supports, which can create turbulence and further contribute to pressure loss.

A study by the U.S. Department of Energy suggests that optimal piping layout can improve air delivery efficiency by up to 80%. Ensuring straight runs and minimizing elbows not only streamlines airflow but also reduces the risk of energy loss and system wear, enhancing the longevity and reliability of the compressed air system.

Maintaining an efficient air piping system is crucial for maximizing performance and ensuring longevity. Regular inspections should be a part of your routine maintenance, as they can help identify leaks or other issues before they escalate. Look for signs of wear and tear, such as rust or corrosion, and address these concerns promptly. Implementing a schedule for checking connections, fittings, and joints can prevent costly downtime and maintain optimal airflow.

Another important aspect of maintenance is keeping your air piping clean and free from contaminants. Moisture can accumulate within the pipes, leading to decreased efficiency and potential damage. Consider installing moisture separators and filters to mitigate this issue. Additionally, periodically flushing the system can help eliminate debris and ensure that air flows as intended. By taking proactive steps in maintenance, you can extend the life of your compressed air piping system and maintain its performance at peak levels.

Please share your email with us to see your results.