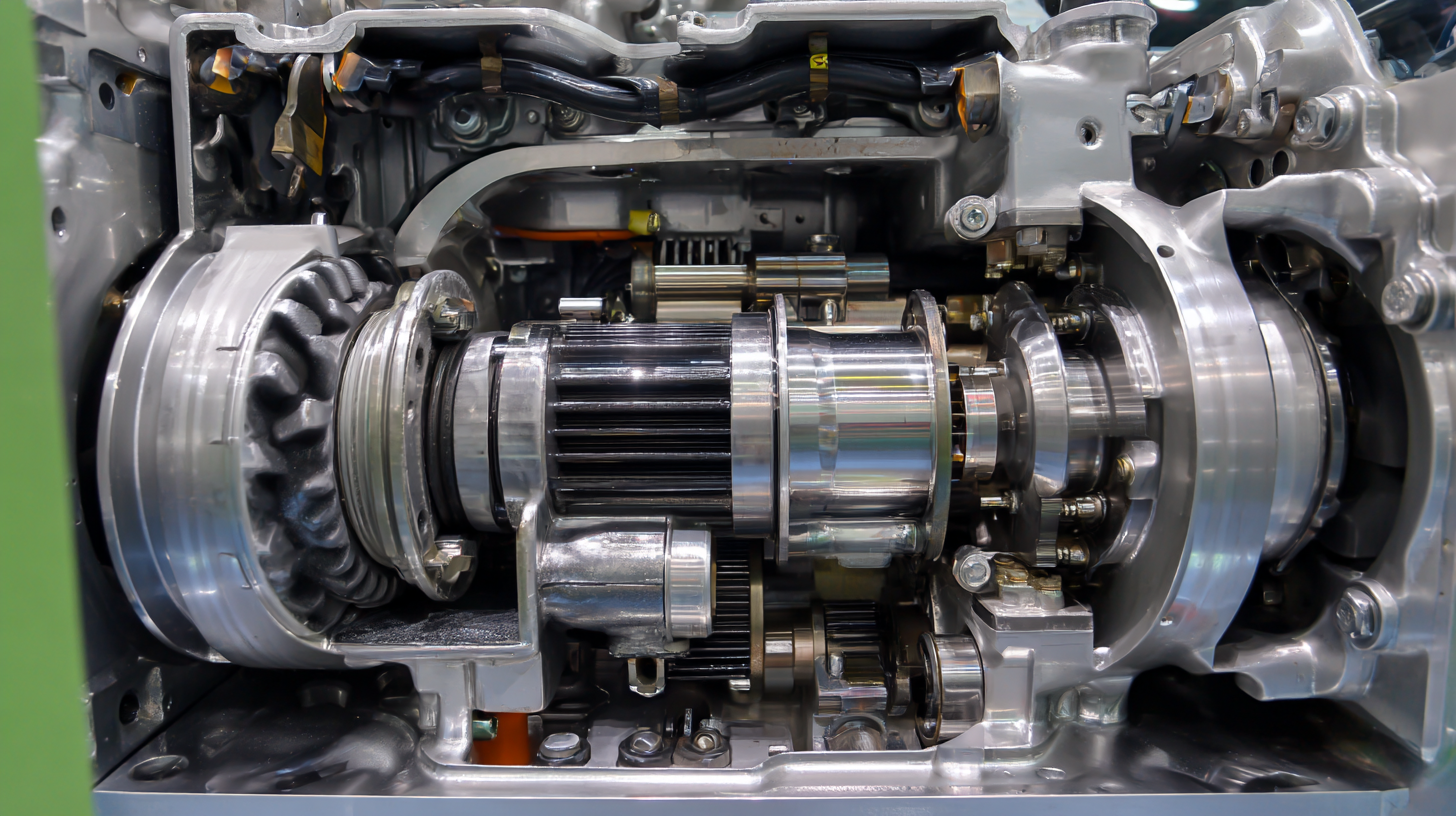

In modern refrigeration systems, the rotary compressor plays a pivotal role in enhancing efficiency and optimizing performance. This type of compressor is characterized by its compact design and ability to operate silently, making it a popular choice in both residential and commercial applications.

Understanding the mechanics behind rotary compressors is essential for engineers and technicians aiming to improve energy consumption and system reliability.

These compressors function by utilizing rotating elements to compress refrigerants, allowing for effective heat exchange and temperature regulation. As the demand for energy-efficient refrigeration solutions grows, exploring the intricacies of rotary compressor technology becomes imperative for the development of sustainable cooling systems. This introduction aims to delve into the operational principles, advantages, and potential advancements of rotary compressors in contemporary refrigeration practices.

These compressors function by utilizing rotating elements to compress refrigerants, allowing for effective heat exchange and temperature regulation. As the demand for energy-efficient refrigeration solutions grows, exploring the intricacies of rotary compressor technology becomes imperative for the development of sustainable cooling systems. This introduction aims to delve into the operational principles, advantages, and potential advancements of rotary compressors in contemporary refrigeration practices.

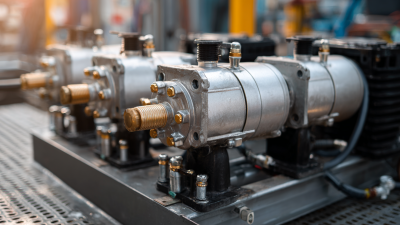

Rotary compressors are vital components in modern refrigeration systems, playing a crucial role in enhancing efficiency and performance. When evaluating their effectiveness, several metrics come into play. One prominent measure is the Coefficient of Performance (COP), which reflects the ratio of cooling output to energy input. Higher COP values indicate greater efficiency, making rotary compressors a popular choice for various refrigeration applications. Additionally, energy consumption per ton of refrigeration is another critical metric, as it directly impacts operational costs and energy usage.

Tips for maximizing the efficiency of rotary compressors include:

Rotary compressors have emerged as a dominant choice in modern refrigeration systems, primarily due to their enhanced efficiency compared to traditional technologies.

According to market analysis, the global air compressor market, which includes rotary, centrifugal, and reciprocating models, is projected to reach USD 16433.3 million by 2033. This projected growth highlights the increasing adoption of rotary compressors, which are favored for their compact size and lower energy consumption. When compared to reciprocating compressors, which are notable for their high energy usage, rotary compressors typically exhibit greater reliability and operational efficiency.

Rotary compressors have emerged as a dominant choice in modern refrigeration systems, primarily due to their enhanced efficiency compared to traditional technologies.

According to market analysis, the global air compressor market, which includes rotary, centrifugal, and reciprocating models, is projected to reach USD 16433.3 million by 2033. This projected growth highlights the increasing adoption of rotary compressors, which are favored for their compact size and lower energy consumption. When compared to reciprocating compressors, which are notable for their high energy usage, rotary compressors typically exhibit greater reliability and operational efficiency.

Tips: When selecting a compressor type, consider not only the initial cost but also the long-term energy consumption. Rotary compressors often provide better performance in continuous operation scenarios, making them ideal for industrial applications.

In the realm of compressor technologies, the capability to regulate suction valve capacity effectively has gained traction, especially in reciprocating types. This regulation is crucial for optimizing performance and minimizing energy wastage. As industries explore sustainable practices, the shift towards more efficient rotary compressors is evident, as they can significantly reduce both operational costs and environmental impact.

The efficiency of rotary compressors in modern refrigeration systems is significantly influenced by the choice of refrigerants. Recent studies indicate that the selection of low-global warming potential (GWP) refrigerants, such as hydrocarbons (R290, R600a) and HFO R1234yf, can enhance compressor performance while reducing environmental impact. For instance, experimental investigations demonstrate that these alternatives can outperform traditional refrigerants like R134a in specific applications, contributing to improved energy efficiency and lower carbon footprints.

The growing air conditioning compressor market, projected to expand from USD 30.0 billion in 2025 to USD 48.9 billion by 2035, reflects a shift towards more efficient technologies. With a compound annual growth rate (CAGR) of 5.0%, the demand for rotary compressors, which play a vital role in air conditioning systems, is expected to rise. This growth is further driven by the increasing use of innovative refrigerants that leverage the operational advantages of rotary compressors, thereby enhancing overall system efficiency. As refrigerant technology evolves, the impact on compressor performance becomes increasingly evident, highlighting the critical relationship between refrigerant selection and energy efficiency in refrigeration systems.

| Refrigerant Type | COP (Coefficient of Performance) | Power Consumption (kW) | Cooling Capacity (kW) | Efficiency (%) |

|---|---|---|---|---|

| R-410A | 3.5 | 1.5 | 5.25 | 85 |

| R-134A | 3.0 | 1.6 | 4.80 | 75 |

| R-32 | 3.8 | 1.4 | 5.32 | 90 |

| R-1234yf | 3.2 | 1.7 | 5.44 | 80 |

| R-22 | 3.1 | 1.55 | 4.81 | 77 |

Rotary compressors have become a cornerstone in modern refrigeration systems, mainly due to their superior design features that significantly enhance performance. One notable aspect is the incorporation of advanced materials that improve thermal efficiency, allowing rotary compressors to operate at lower temperatures while maintaining optimal cooling capacity. Additionally, the precise engineering of the rotor and stator ensures minimal friction and wear, which translates to a longer lifespan and reduced maintenance needs.

Tips: When selecting a rotary compressor, consider models equipped with variable speed drives. This feature adjusts the compressor's speed based on cooling demands, leading to energy savings and enhanced efficiency. Moreover, pay attention to the noise level ratings, as quieter compressors can enhance the comfort of indoor environments.

Another key feature is the use of advanced lubrication systems that ensure smooth operations, reducing the risk of overheating and bearing failure. These systems often utilize oil that remains stable across a range of temperatures, ensuring consistent performance even under varying load conditions. Ultimately, these innovations not only optimize energy efficiency but also contribute to the overall reliability of refrigeration systems.

Tips: Regularly check and maintain the lubrication system to ensure it functions effectively. Proper maintenance can prevent many common compressor issues, extending the life of your refrigeration system.

Modern refrigeration systems are increasingly integrating advanced technologies, among which rotary compressors stand out due to their energy efficiency and performance. Recent case studies illustrate significant energy savings achieved by utilizing rotary compressors in various applications across smart cities. These systems not only help in reducing power consumption but also contribute to lower greenhouse gas emissions, supporting the broader goals of sustainable urban development.

One prominent example is the implementation of rotary compressors in supermarket refrigeration systems. By adopting these efficient machines, several stores reported energy savings of up to 30%, which not only cuts operational costs but also aligns with growing environmental regulations. As cities grapple with "urban disease" issues stemming from rapid urbanization, energy-efficient solutions like rotary compressors become vital in promoting healthier living environments.

Tips: When looking into refrigeration systems for your business, consider models featuring rotary compressors that offer variable speed operation. This enhances efficiency as it adjusts compressor speed based on cooling demand. Additionally, regular maintenance is essential to ensure optimal performance and longevity of your refrigeration units, further maximizing energy savings.

Please share your email with us to see your results.