Choosing the right refrigerated air dryer is crucial for various applications. This equipment helps remove moisture from compressed air, ensuring optimal system performance. A poorly chosen dryer can lead to issues like rust, corrosion, and equipment failure.

Consider your specific needs before making a decision. Think about air flow rates, operating temperature, and required pressure. The wrong air dryer may not handle the load properly, resulting in inefficiency. It can also cause unexpected downtime.

Take time to research and compare different models. Read reviews and gather feedback from users. Remember, investing in a quality refrigerated air dryer pays off in the long run. However, many overlook essential details in this selection process. Reflect on your requirements carefully, as this will impact your operation significantly.

Refrigerated air dryers play a crucial role in compressed air systems. They help eliminate moisture from the air. Moisture can damage equipment and reduce efficiency. An air dryer cools the compressed air, causing moisture to condense and drain away. This process is essential to maintain the quality of compressed air.

Selecting the right refrigerated air dryer requires understanding your needs. Factors include air flow rate, the operating environment, and humidity levels. Not every system is the same. Sometimes, users might underestimate their moisture load. This can lead to problems like freeze-ups in the system. Regular maintenance is also vital. Clogged filters can hinder performance and reduce efficiency.

When choosing an air dryer, consider its energy consumption. Some models consume more energy than others. Efficiency can lead to significant cost savings over time. It’s also important to think about the placement of the dryer. A poorly placed unit may not perform well. Always evaluate how your specific application will interact with the dryer’s capabilities.

| Model | Max Flow Rate (CFM) | Pressure Rating (PSI) | Temperature Range (°F) | Power Consumption (kW) | Dimensions (inches) | Weight (lbs) |

|---|---|---|---|---|---|---|

| Model A | 50 | 100 | 35 - 50 | 1.5 | 24 x 24 x 36 | 150 |

| Model B | 75 | 125 | 40 - 55 | 2.0 | 30 x 30 x 42 | 180 |

| Model C | 100 | 150 | 35 - 60 | 2.5 | 36 x 36 x 48 | 220 |

Choosing the right refrigerated air dryer requires attention to various factors. One critical aspect is the airflow capacity. According to industry reports, selecting a dryer with the right CFM (cubic feet per minute) rating is vital. Oversizing can lead to inefficiencies. Undersizing may cause moisture issues. Understand your system's requirements before making a decision.

Another key factor is the operating temperature. Most dryers operate effectively within a specific range. Operating outside this range can reduce efficiency and increase energy costs. Controlling the inlet temperature is crucial. Many users overlook this aspect.

**Tip:** Always monitor your existing system's performance metrics. This data can help in making an informed choice.

Energy efficiency ratings matter too. According to a survey by PneuDrive, cooling and heating comprise a significant portion of air dryer energy consumption. Look for models with lower kW per CFM ratios to save on energy costs. Each small percentage in efficiency can add up over time.

**Tip:** Regular maintenance is essential. Dirty filters can compromise efficiency, leading to higher operating costs. Replacing them regularly is a sound strategy for long-term savings.

Finally, consider the features that matter most to you. Basic models might lack the advanced monitoring systems found in newer designs. Reflect on what functionalities you truly need. This reflection will guide your purchasing decision effectively.

This chart compares the maximum airflow capabilities (CFM) of different refrigerated air dryers, highlighting their performance to help you make informed decisions based on your specific needs.

When selecting a refrigerated air dryer, understanding capacity and flow rates is crucial. Refrigerated air dryers typically range from 1 to 1,000 CFM (cubic feet per minute). Choosing one too small can lead to inadequate moisture removal. Conversely, oversizing can waste energy and lead to frequent cycling.

Flow rate measurements are not constant. They can fluctuate based on temperature, humidity, and pressure conditions. For example, at 100°F inlet temperature, a dryer rated for 50 CFM may perform differently than expected. Some reports suggest that at higher temperatures, efficiency may drop by as much as 20%.

It's essential to consider your facility's peak demand times. Underestimating required capacity can result in operational problems. Regular evaluation of your system will reveal if adjustments are necessary. This reflection can save costs and improve performance in the long run. Always recommend consulting with experts to optimize your specific setup.

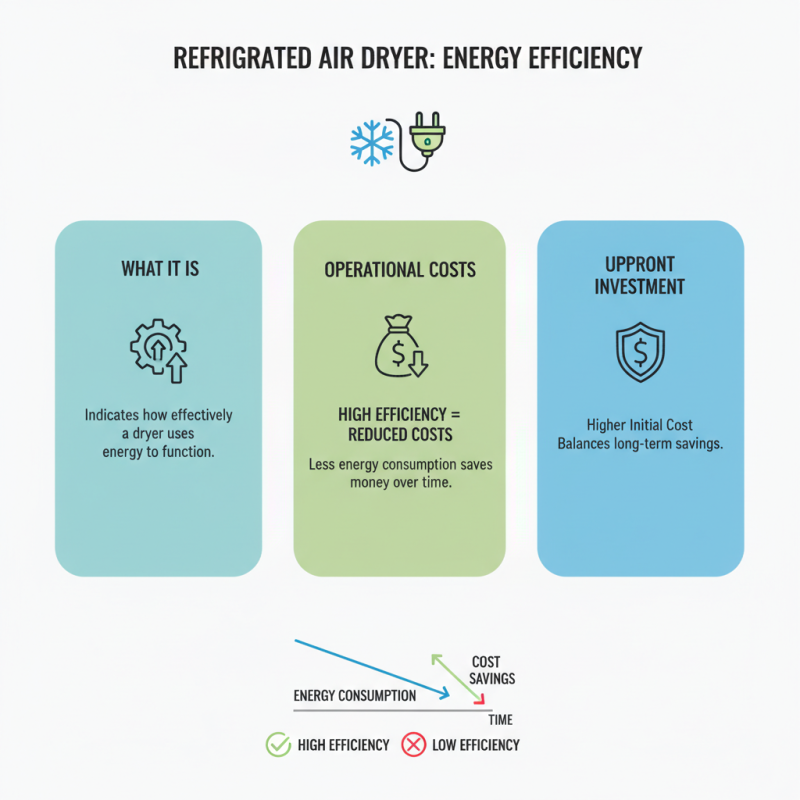

When selecting a refrigerated air dryer, energy efficiency ratings play a crucial role. These ratings indicate how effectively a dryer uses energy to function. Highly efficient models can significantly reduce operational costs. If a dryer consumes less energy while meeting your performance needs, it can save money in the long run. However, the upfront cost could be higher.

Consider the specific needs of your application. Different environments require varying degrees of moisture removal. Sometimes, energy-efficient dryers might not perform adequately in high-demand scenarios. This could lead to increased moisture levels, impacting equipment and product quality. You want a balance between efficiency and capacity. Reflect on how often you operate your machinery. Frequent use can amplify energy savings from more efficient systems.

It's essential to evaluate both performance and cost. A dryer that saves energy but cannot handle your production level may not be the best choice. Review your options carefully. Think about future growth, too. Investing in an efficient model might offer benefits down the line. Choosing the right refrigerated air dryer deserves thorough analysis and consideration.

Refrigerated air dryers play a crucial role in many industries. Their primary function is to remove moisture from compressed air systems. This process prevents corrosion and damage to machinery. Industries like food processing, automotive, and pharmaceuticals often rely on these systems. In such applications, a reliable air supply is essential for maintaining product quality and safety.

One key industry standard for refrigerated air dryers is the dew point temperature. A lower dew point means dryer air and better performance. Different applications require different dew points. For example, food packaging may need a dew point of 35°F (-2°C), while manufacturing processes might settle for 50°F (10°C). Selecting a dryer that meets these requirements is vital. However, it's easy to overlook the specific needs of your operations, leading to poor decisions.

Another aspect to consider is energy efficiency. Refrigerated air dryers consume considerable energy. Some models may offer advanced technology to reduce energy use. Yet, not all users are aware of these options. This oversight can lead to higher operational costs over time. Evaluating the energy requirements of your application can help you choose wisely. A dryer that aligns with your needs can result in savings and improved efficiency.

Please share your email with us to see your results.