Selecting the right nitrogen generation system is essential for various industries. This decision can impact efficiency and cost-effectiveness. With diverse options available, it’s important to identify your specific needs before making a choice.

A good nitrogen generation system should align with your production requirements. Consider factors such as purity levels, flow rates, and installation space. These details can help narrow down your options. Not all systems will fit every application perfectly.

Mistakes in this process can lead to wasteful spending or downtime. Reflect on your current practices and future needs. It’s crucial to balance immediate requirements with long-term goals. Seeking insight from experts and user reviews can further refine your decision.

Nitrogen generation systems are essential in various industries, providing a reliable source of nitrogen for diverse applications. These systems typically operate via two primary technologies: membrane separation and pressure swing adsorption (PSA). Membrane separation systems are efficient, producing high-purity nitrogen quickly. They are often favored for smaller applications, where immediate nitrogen is needed. On the other hand, PSA systems excel in larger-scale operations, delivering nitrogen at lower costs per volume.

Understanding the basics of these technologies helps in determining the right system for specific needs. PSA systems, for instance, often achieve nitrogen purity levels between 95% and 99.9%. According to industry data, a well-implemented nitrogen generation system can reduce operational costs by up to 50%. However, it's crucial to consider factors such as gas flow rate requirements and specific purity levels. Sometimes, users overestimate their nitrogen needs, leading to unnecessary expenditures.

Additionally, maintenance plays a critical role in performance. Regular checks are necessary to prevent inefficiencies. Without proper upkeep, systems can underperform, leading to increased operational costs. Businesses must reflect on their needs and usage patterns. Adapting the nitrogen generation system to these factors leads to better performance and cost efficiency. However, too much reliance on one type of system might hinder flexibility in future operations.

When selecting a nitrogen generation system, understanding the types of technologies available is crucial. Different methods suit different needs. Common systems include pressure swing adsorption (PSA), membrane nitrogen generators, and cryogenic distillation. Each has its strengths and weaknesses, prompting users to think about their unique requirements.

PSA systems are popular because they efficiently produce high-purity nitrogen. They rely on adsorption principles, which can be quite effective. However, they may not be suitable for all scales of operation. Membrane systems, on the other hand, are simpler and often more compact. They separate nitrogen from air using a semi-permeable membrane. This method can be effective for smaller applications but might not provide purities as high as PSA systems.

Tips: Assess your volume needs before deciding. Consider the purity levels you require. If your demand is variable, think about systems that can adapt. Reflect on the operational costs long term. Each technology has its operational quirks. A system that works for one application might not be ideal for another. Make sure you investigate thoroughly before investing.

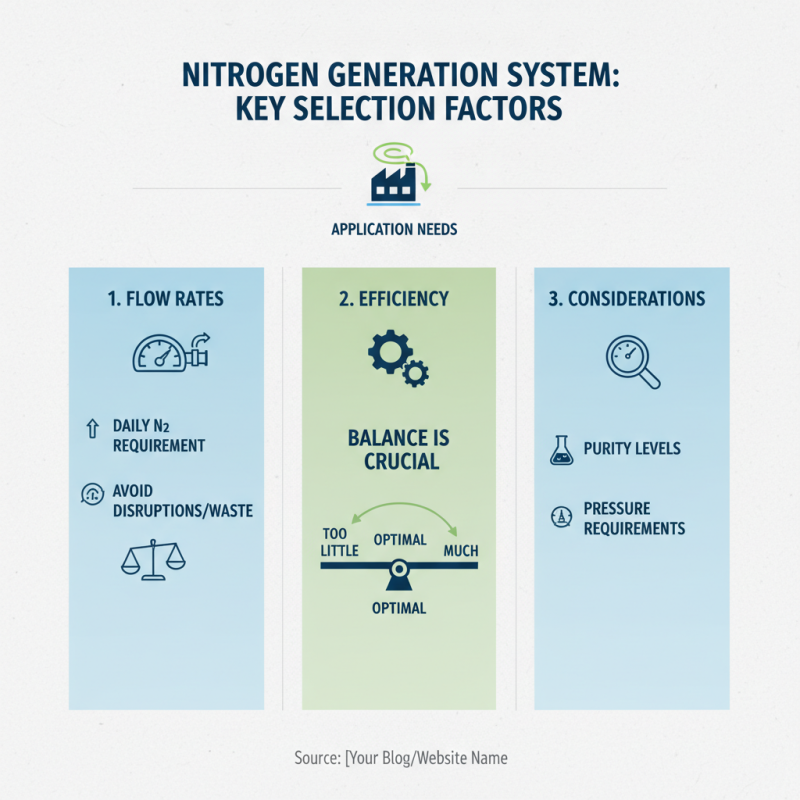

When selecting a nitrogen generation system, key factors are crucial to ensure it meets your application needs. Consider flow rates. Determine how much nitrogen you require daily. Too little nitrogen can disrupt your operations. Too much can lead to waste. Balance is essential for efficiency.

Purity levels are another vital factor. Different applications demand various purity levels. Some industries require 99.999% nitrogen, while others may function well with lower purification. Understand your specific requirements. Test samples if necessary to ensure the generated nitrogen meets your standards.

Another factor is the system's footprint. Space constraints can impact your choice significantly. Some systems require extensive setup, while others are compact and mobile. Evaluate the installation site carefully. Also, consider maintenance needs. Regular upkeep can be time-consuming. Reflect on how this will affect your staff and resources.

When evaluating nitrogen generation systems, cost and efficiency are crucial. According to industry reports, the total cost of ownership includes initial setup, maintenance, and operational expenses. A recent study shows that onsite nitrogen generation can reduce costs by up to 40% compared to traditional nitrogen supply methods. This is significant for industries where nitrogen is essential, such as food packaging or pharmaceuticals.

Efficiency plays a vital role in selecting a system. Systems with higher purity levels often operate more effectively. Some nitrogen generators can achieve purities above 99.9%. However, this comes at a price. A detailed analysis should include flow rate requirements and nitrogen purity to determine the right fit for specific applications.

Tips: Always evaluate your current nitrogen needs. Conduct a cost-benefit analysis to see long-term savings. Look for systems with energy-saving features. Some systems may seem cost-effective initially, but hidden costs can emerge. Be cautious about operational costs and gauge the potential for enhancements. Selecting the right system involves not just initial investment but ongoing expenses too.

When selecting a nitrogen generation system, maintenance and support are key. A reliable service plan is crucial for long-term performance. Think about how often you will need maintenance. Regular checks can prevent costly downtime and ensure efficiency.

Tips: Always ask about service agreements before finalizing your purchase. Understanding the details of these agreements is vital. A system may look good on the surface, but if support is lacking, issues can arise quickly.

Pay attention to the availability of technical support. A knowledgeable team can help troubleshoot problems effectively. Consider response times for service calls. A rapid response can minimize disruptions to your operations. Reflect on previous experiences with equipment support. Ups and downs in service quality can influence your decision.

Evaluate training opportunities for your staff. A system is only as good as the people who operate it. Well-trained personnel can extend the life of the equipment and reduce errors. Knowledge gaps can lead to operational hiccups. Ensure your team knows maintenance basics to avoid neglect.

Please share your email with us to see your results.