When selecting an air compressor air dryer, expertise matters. Industry specialist, John Smith, emphasizes, "The right air dryer can enhance efficiency and prolong equipment life." Choosing the best dryer is not a simple task. Various factors must be considered, and each decision can impact performance.

Look at your specific needs. Consider your compressor's capacity. A small shop might not require the same air dryer as a larger industrial facility. Size matters in this context. Additionally, remember that different air dryers serve different purposes. Refrigerated dryers, for example, excel in general applications, while desiccant dryers are for more demanding environments.

Many users overlook the importance of proper maintenance. Filters must be changed regularly. Ignoring this can lead to reduced efficiency. Sometimes people choose based solely on price, which can lead to costly mistakes. Reflecting on these details can lead to better choices and improved results in your operations.

Air dryers play a crucial role in air compressor systems. They help remove moisture from compressed air, preventing damage to equipment and improving efficiency. According to industry reports, about 80% of all air system failures are caused by moisture. This highlights the importance of having a reliable air dryer.

Moisture in compressed air can lead to rust, corrosion, and product defects. Thus, choosing the right air dryer is essential. For instance, refrigerated dryers are popular for general use. They chill the air, condensing the moisture into water, which is then drained away. On the other hand, desiccant dryers absorb moisture, providing drier air at lower temperatures.

Tips: Assess your specific air quality needs. Evaluate your local climate and how much moisture you expect in your air supply. Regularly check and maintain your dryer. Even the best systems require care to function optimally. Remember, investing in a quality air dryer can save you money on repairs and replacements in the long run.

Humidity plays a crucial role in determining the right air dryer for your air compressor. High humidity levels can lead to moisture accumulation in the compressed air. This can cause damage to your equipment and affect product quality. Understanding your environment is key. Measure the humidity levels accurately to ensure proper performance.

Consider the drying performance standards required for your applications. Some tasks may need extremely dry air, while others may tolerate a bit of moisture. Evaluate the specific requirements of your processes. A detailed analysis helps in selecting the appropriate drying method. Remember, a bad choice may lead to inefficiencies. Explore different options, like refrigeration or desiccant dryers, and their impact on your system.

Many users underestimate the consequences of inadequate drying. Producing air that is too humid can ruin the finish on painted surfaces. Take time to reflect on past mistakes. What went wrong when moisture was ignored? Identifying these issues can inform better decisions down the line. Always prioritize your specific drying needs before making a purchase.

When choosing an air dryer for your compressor, it's essential to understand the differences between desiccant and refrigerated types. Desiccant dryers utilize moisture-absorbing materials to remove humidity. They are best for environments requiring extremely dry air, like in food packaging or pharmaceuticals. However, they require regular maintenance and replacement of desiccant material.

On the other hand, refrigerated dryers cool the air to condense moisture. They are typically more straightforward and easier to maintain. These dryers work efficiently in most applications. However, they might not achieve the same low humidity levels as desiccant dryers. Considering your specific needs is crucial.

If your operation demands high air quality, desiccant might be your answer. But, if maintenance is a concern, refrigerated drying may suit you better. Reflecting on your priorities will guide you in choosing the right system.

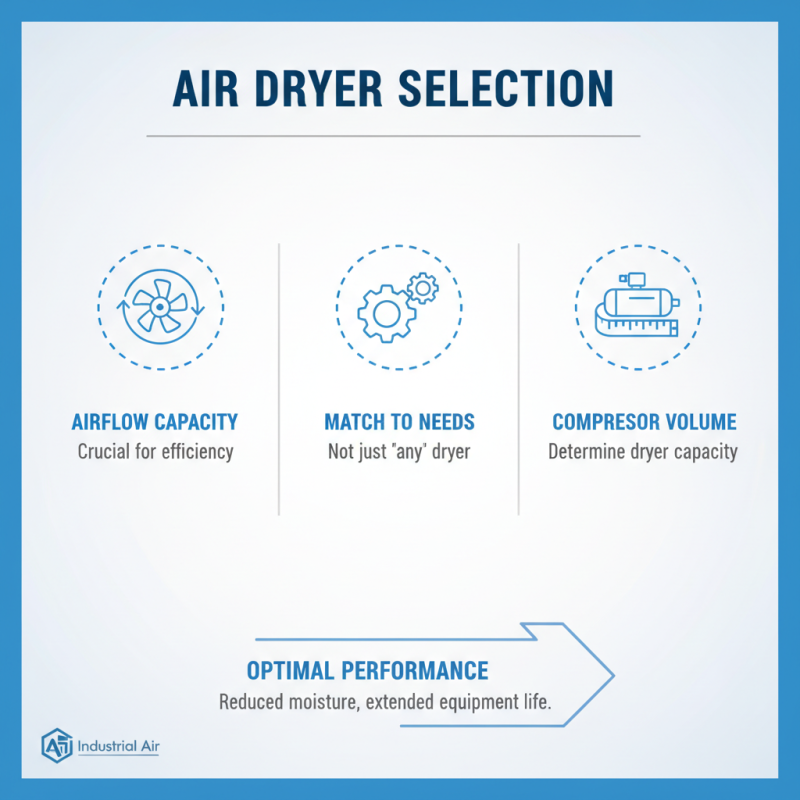

When selecting an air dryer for your air compressor, airflow capacity is crucial. It's not just about picking any dryer; you must match it to your specific needs. Understand the volume of air your compressor generates. This will help you determine the required dryer capacity.

A common mistake is underestimating airflow demands. If your applications require high air usage, a smaller dryer will struggle. This could lead to moisture problems and reduced efficiency. Conversely, a too-large dryer can be unnecessary and waste energy. Consider your tools and machines. List their airflow requirements to avoid mismatches.

Pay attention to the specifications. Look for the dryer’s maximum airflow rating. Compare it with your compressor’s output. Check the drying temperature range as well. If the dryer operates outside this range, your equipment might not function optimally. Think through these details carefully. Mistakes can be costly.

When selecting an air dryer for your air compressor, cost is a significant factor. Initial investment matters, but long-term efficiency holds equal weight. You might find a cheaper option, yet it could lead to high energy costs later. It's essential to evaluate the efficiency ratings of different models. Look for dryers that consume less energy while maintaining performance.

Consider your specific needs. Will the dryer run continuously or intermittently? Your usage pattern impacts energy consumption. A unit that runs less often may seem cost-effective upfront but could waste energy more quickly during use. Also, check maintenance costs. Some dryers require more frequent servicing, which can add up over time.

Don't overlook your space constraints. A compact design may save space, but ensure that it meets your airflow requirements. Balancing these choices is vital. There's no one-size-fits-all solution. Reflect on your priorities. Investing a bit more now could pay off in reduced energy bills and extended equipment life. Each decision carries weight, so take the time to assess your options carefully.

| Type of Air Dryer | Initial Cost (USD) | Energy Consumption (kWh/year) | Maintenance Cost (USD/year) | Lifespan (Years) |

|---|---|---|---|---|

| Refrigerated Dryer | $1,200 | 1,500 | $150 | 10 |

| Desiccant Dryer | $2,500 | 2,000 | $300 | 15 |

| Membrane Dryer | $3,000 | 1,200 | $100 | 20 |

| Cyclone Dryer | $1,000 | 800 | $75 | 8 |

Please share your email with us to see your results.